Mechanical tests

The

mechanical

characterization

of

materials

(tensile,

compression,

fracture,

bending,

...)

applies

a

wide

range

of

experimental techniques

to

determine

their

behavior

under

various

types

of loading

(monotonic

or

cyclic,

uniaxial

or

multiaxial)

and environmental conditions

(temperature,

humidity,

etc.).

The

Mechanical Testing

Laboratory

has

5

mechanical testing

machines

which, together

with

various

additional equipment and

environmental chambers,

enable to characterize

the

mechanical behavior of

all

materials

used

in

civil

applications

(concrete,

rocks,

metals,

polymers,

...)

subjected

to

diverse mechanical,

thermal

and

environmental actions.

The

mechanical tests

that

may be performed include

those

applying

tensile,

compression,

fracture,

fatigue,

etc..

forces.

The

available equipment

allow

to

perform uniaxial

or

biaxial

mechanical tests

under

monotonic

and

cyclic

loads.

To

record

data

from

tests,

a

wide

range

of

conventional

strain

gauge

systems

are

implemented:

resistive

and

capacitive

gauges.

The

behavior

of the

material

throughout

its

useful life

is

conditioned

by the

environment in

which

they

are,

and

the

interaction between environment and mechanical

loads

can multiply

the

effects

of

both.

To

evaluate

the

interaction

between

environment

and

materials, the

Laboratory

has

three

environmental

chambers

in

which temperature

and

pressure

conditions

are

constantly monitored,

simulating this way

freeze-thaw

conditions

and

other

common

environmental

phenomena.

|

|

|

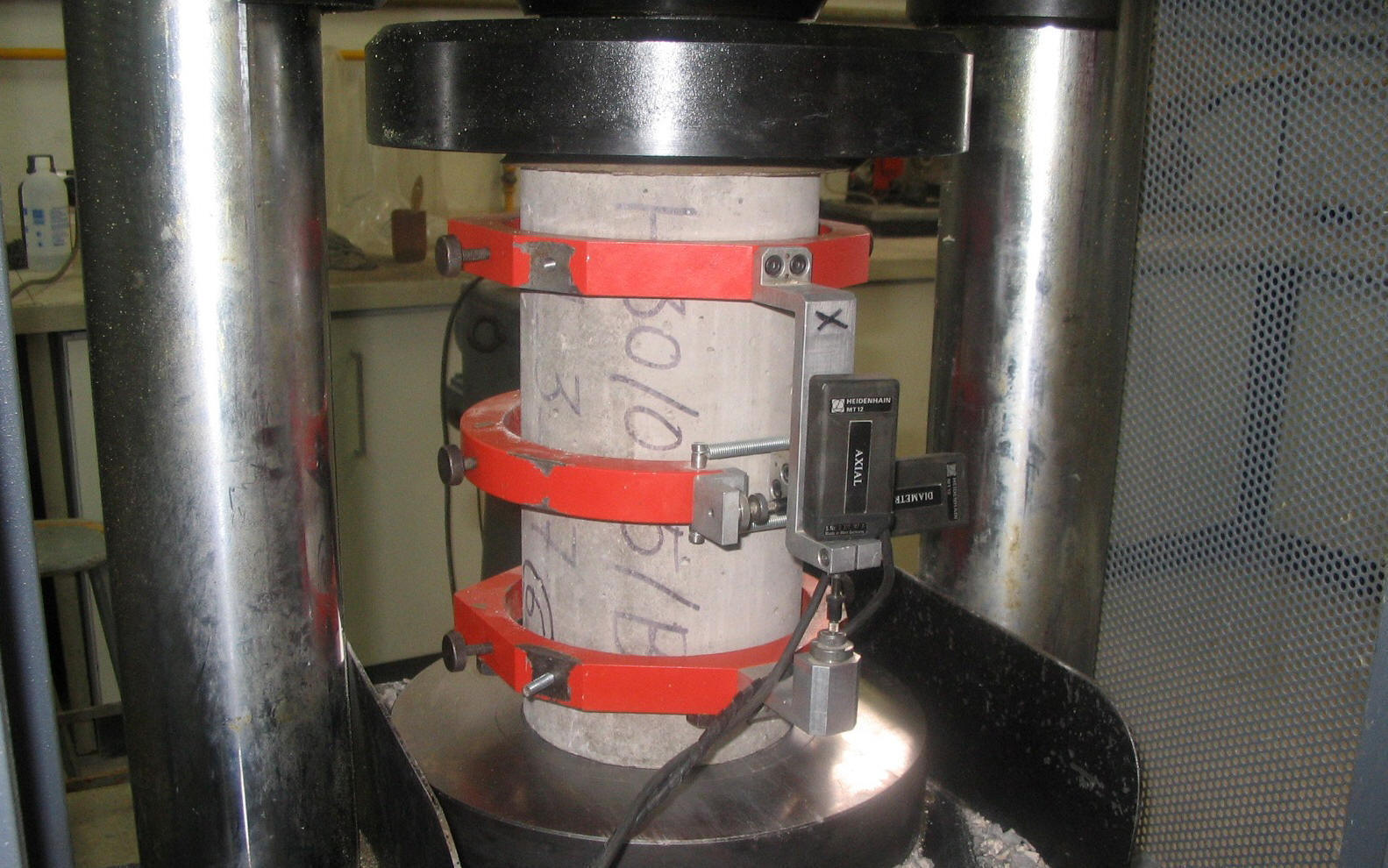

Measurement of compressive strength |

Elastic

Modulus measurement |

|

|

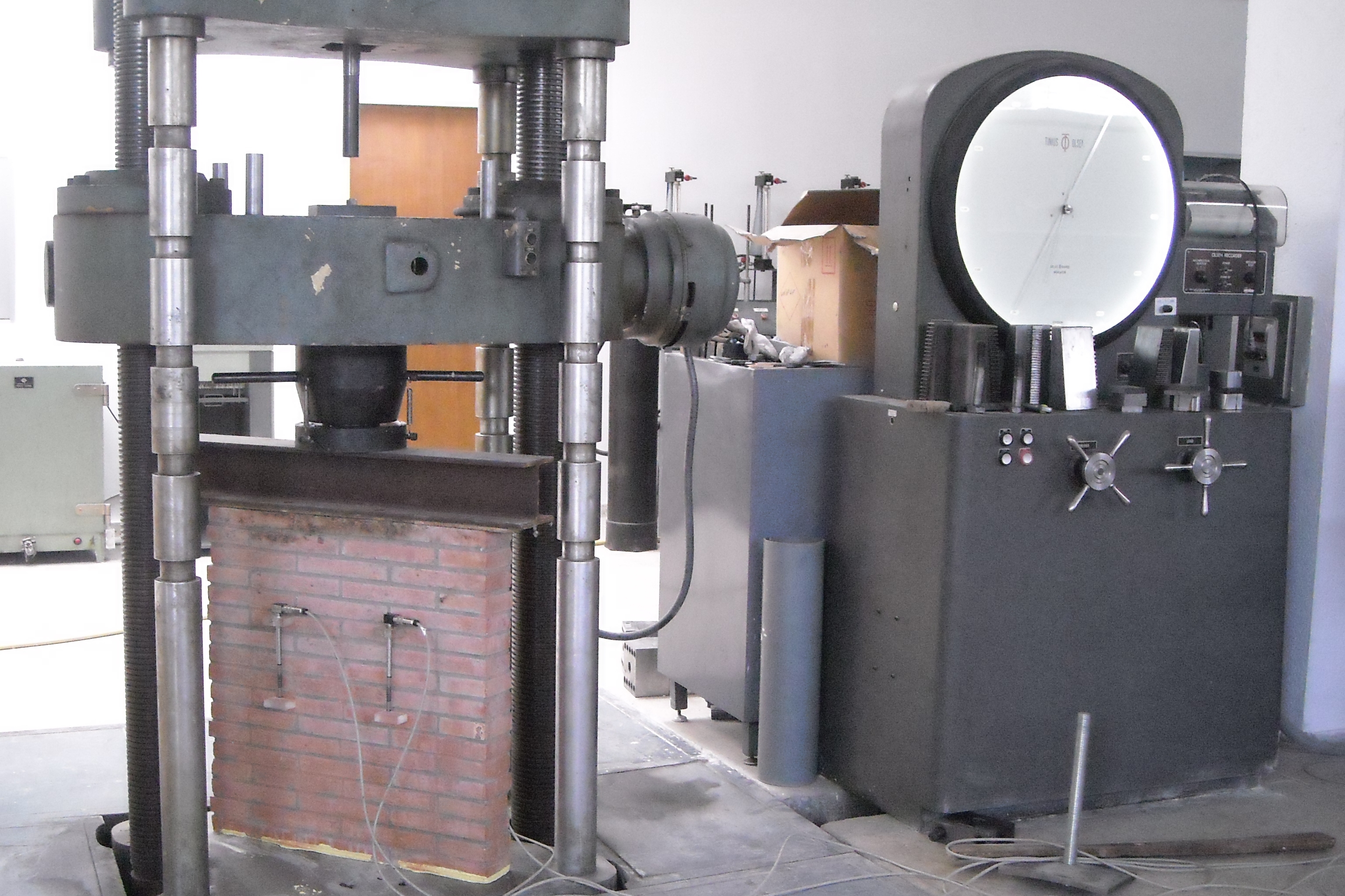

| Compression

test of a masonry wall

|

Compression

test of a masonry pillar |

|

|

|

| Permeability

tester

|

Measurement

of air content in fresh concrete |

|

|

|

|

Measurement of dynamic

modulus with ultrasounds |

Test tube with strain

gages |

|

|

|

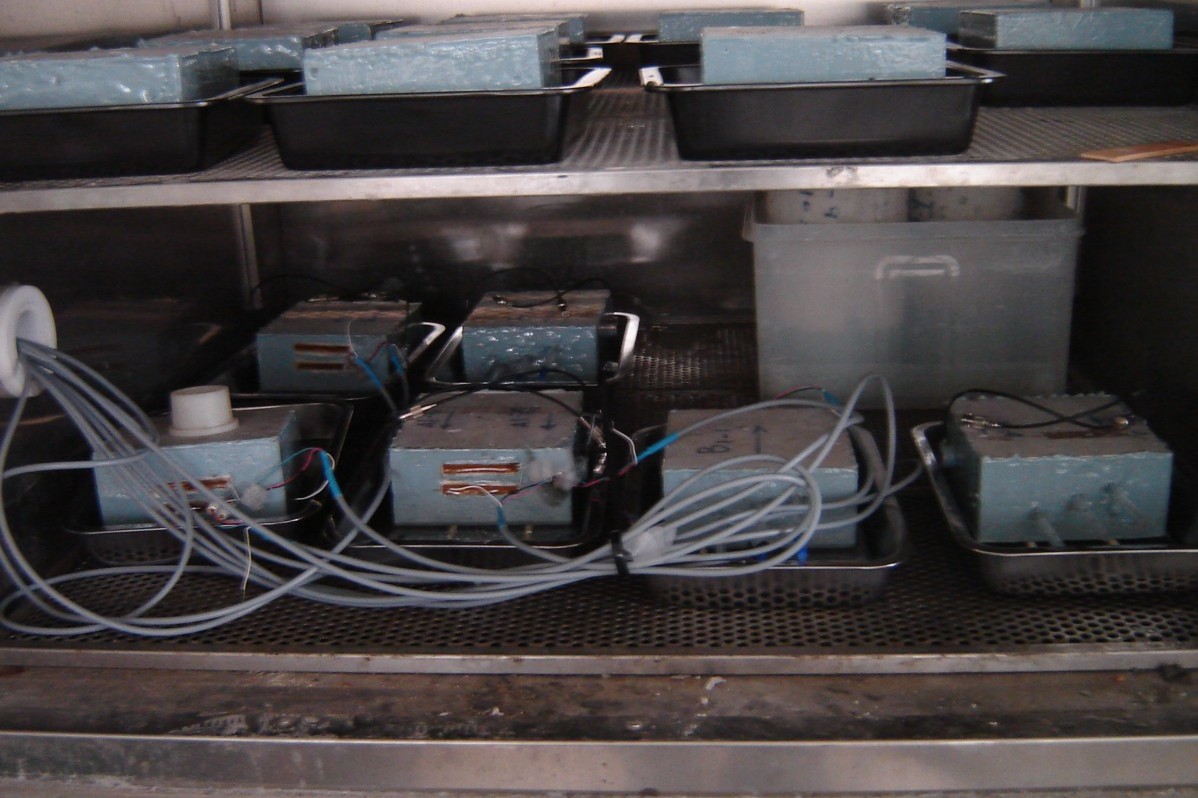

Climatic chamber |

Test tubes in climatic

chamber |

|

|

| Test tube

with sensors of the degree of saturation |